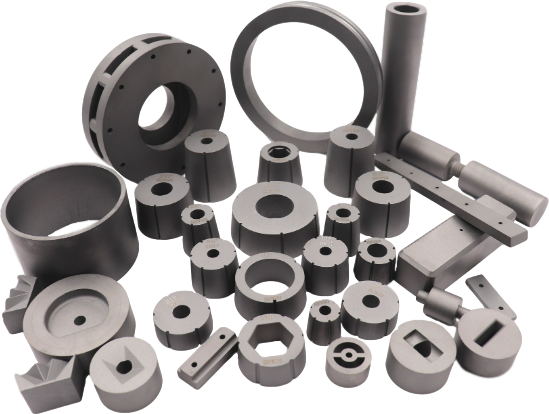

A matsayin sunan carbide hakora na masana'antu, yawancin waɗanda suka yi amfani da shi ba su san yadda ake samar da carbide ba kuma menene bambanci a cikin tsarin samar da shi, a gaskiya ma, masana'antar carbide yana da alaƙa da amfani da muhalli.Misali, carbide don hakar ma'adinai, carbide don hako dutse, csabanikayan aikin juyawa da sauransu duk sun dogara ne akan amfanin muhalli.Akwai kuma misali carbide mai jure lalata da sauransu.

Ta yaya ake samar da Carbide Cemented?Menene tsarin samar da shi?

A samar da tsari na ciminti carbide ne kullum kamar haka: refractory karfe wuya mahadi (tungsten carbide, tantalum carbide, da dai sauransu), bonding karfe (cobalt foda ko nickel foda) da kuma karamin adadin Additives (stearic acid ko esomin) suna hade da kuma ƙasa a cikin matsakaicin niƙa na hexane, kuma ana ƙara slurry na paraffin wax, sa'an nan kuma bushe bushe (ko fesa bushewa), sieved, granulated, da kuma sanya su a cikin gauraye abu;an gano kayan da aka haɗa da kuma cancanta, kuma bayan daidaitattun kayan da aka haɗe an gano su kuma sun cancanta, sannan a danna don yin babban madaidaicin billet;Billet ɗin da aka matse ana juyar da shi ta hanyar ɓata lokaci ko ƙarancin matsi don yinsiminti carbide.

Ƙa'idar haɓakawa

Ana aiwatar da tsarin ɓacin rai ta hanyar dumama a ƙarƙashin yanayi mara kyau, wanda ke da amfani don kawar da ƙazanta, inganta tsabtar yanayi mai tsauri, inganta wettability na lokacin haɗin gwiwa da kuma inganta halayen.Billet ɗin da aka matse yana zafi a cikin yanayin da ba za a iya cirewa ba, kuma yayin da zafin jiki ya tashi kuma ya kai ga yanayin ƙanƙara, yana tserewa daga billet ɗin da aka matse kuma ana riƙe shi na ɗan lokaci kaɗan a matsa lamba na paraffin ƙasa da yanayin zafin, da paraffin. ana fitar da shi daga cikin billet ɗin da aka danne* kuma a dawo da shi, sannan a wanke billet ɗin da aka matse.Yayin da yawan zafin jiki ya ƙara ƙaruwa, billet ɗin yana lalata kuma yana ƙara tsarkakewa, kuma ya biyo baya mai ƙarfi-lokaci.A cikin m lokaci sintering tsari, da zarra (ko kwayoyin) na kowane bangaren a cikin sintered jiki yadawa, barbashi lamba surface yana ƙaruwa, da nisa tsakanin barbashi ragewa, da sintered jiki shrinks kuma an kara ƙarfafa.Lokacin da zafin jiki yana kusa da wurin narkewa na lokacin haɗin gwiwa, lokacin haɗin gwiwa yana fara kwararar filastik, kuma lokacin da yanayin yanayin ruwan ya kai, jikin da aka ƙera yana samar da lokacin ruwa kuma lokacin sintirin ruwa yana faruwa.

A cikin tsari sintering na ruwa lokaci, wani ruwa lokaci Layer bayyana a kan carbide surface, da kumacarbidebarbashi narke a cikin bonding lokaci ta watsawa don samar da wani eutectic, da kuma carbide barbashi recrystallize da girma cikin girma ta cikin ruwa lokaci, sabõda haka, m carbide barbashi suna a hankali nasaba, da sintered jiki shrinks kara da densifies sauri.Jikin da aka ɓalle yana ƙara raguwa kuma yana raguwa da sauri.Ana gudanar da shi a yanayin zafi sama da yanayin zafin yanayin ruwa na wani ɗan lokaci don ba da damar aikin simintin ya ci gaba sosai, sannan a sanyaya.

A cikin tsarin sintiri, jikin da aka yi amfani da shi yana raguwa zuwa kusa da ba porosity ba, kuma an samar da jerin tasirin physicochemical da gyare-gyare na ƙungiya, wanda ya haifar da samuwar simintin carbide mai yawa tare da wani nau'i na sinadarai, kayan jiki da na inji, da kuma tsarin kungiya.

Lokacin aikawa: Juni-29-2023