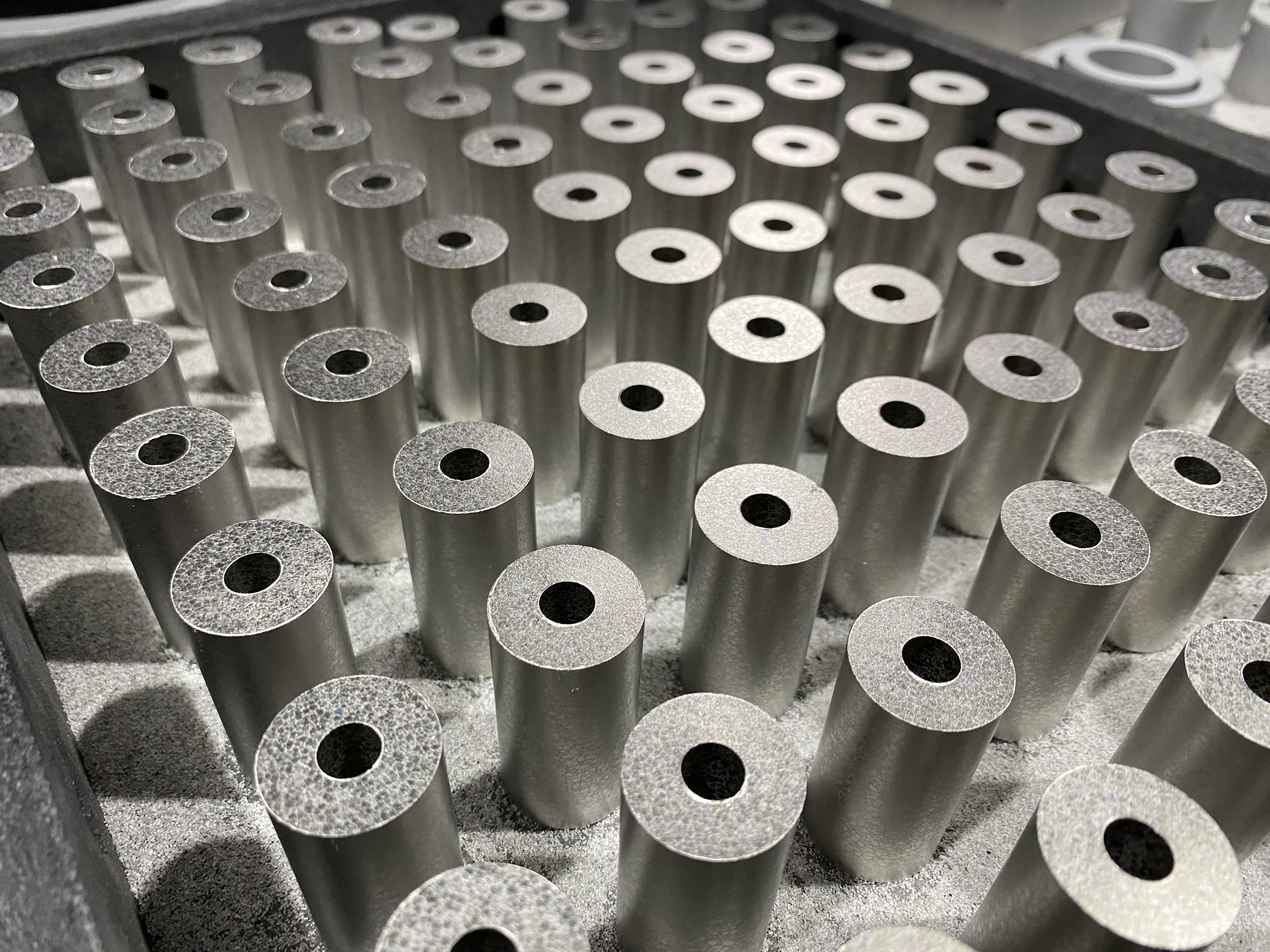

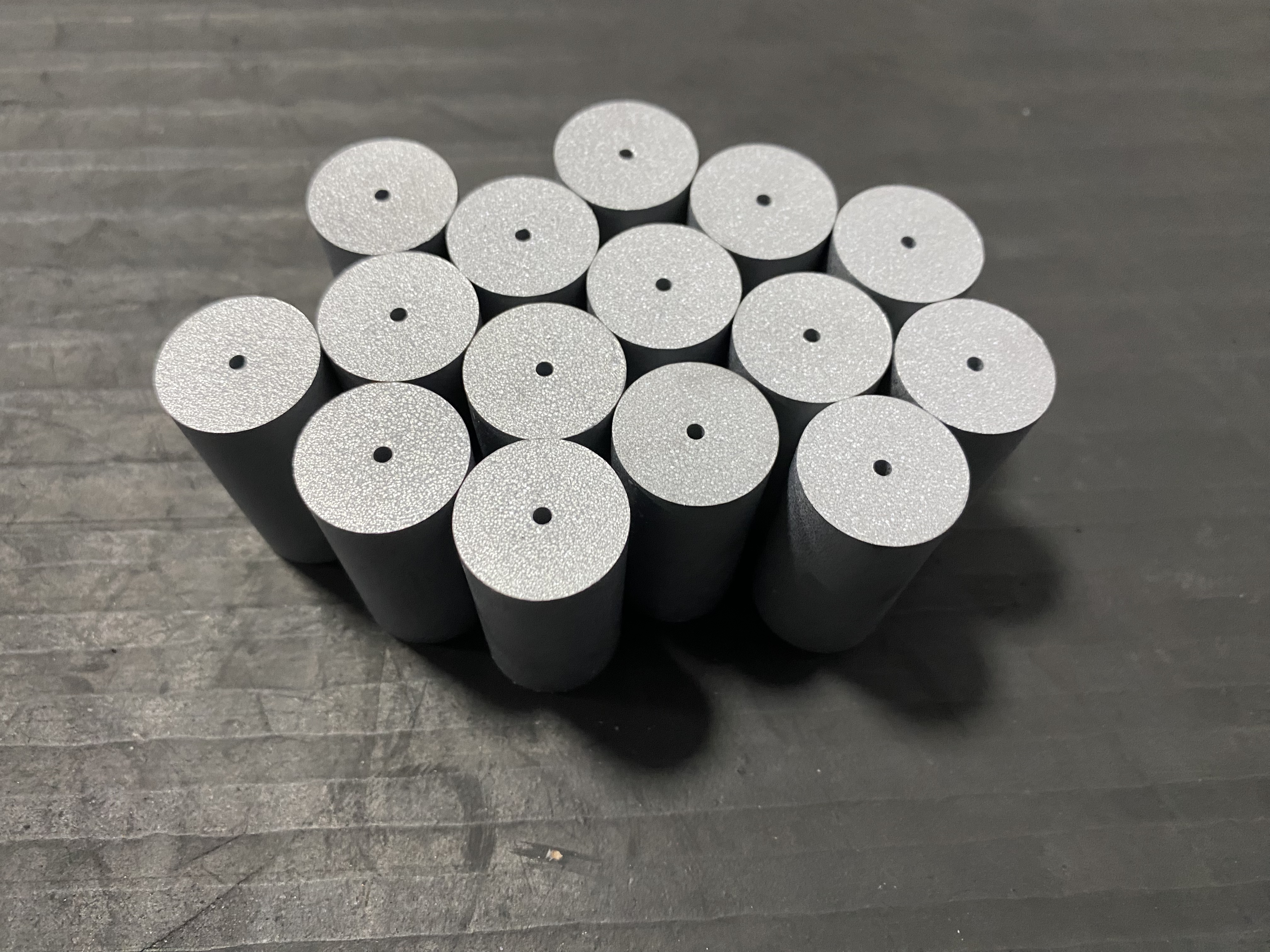

Siminti carbidegyare-gyaren shine a haɗa foda mai gauraya don samun ƙimar da ake buƙata da daidaituwar yawa, da siffar da ake buƙata.

Tsarin samar da ƙananan sifofi da daidaiton ƙira yana buƙatar cewa ƙaƙƙarfan ƙaƙƙarfan dole ne ya sami takamaiman ƙarfi.Dangi da yawa na karamin abu gabaɗaya kusan 50%

A hannun dama, karancin yawa ya yi ƙasa da ƙarancin sa da kuma saƙoƙin ba za a iya ƙi shi gaba ɗaya ba.Idan ya yi tsayi da yawa, ba za a iya kammala latsawa ba ko lahani kamar ƙarami da tsagewa na iya faruwa.Ƙirƙira ita ce mafi kyawun aiki a cikin siminticarbidesamarwa kuma shine maɓalli mai mahimmanci don tabbatar da daidaito, ingantaccen inganci da ingancin ciki nababu komai.Akwai hanyoyin gyare-gyare da yawa don siminti carbide, kamar matsawa gyare-gyare, gyare-gyaren extrusion, gyaran allura, sanyi isostatic latsa-yanke gyare-gyare, da dai sauransu.

Daga cikin su, yin gyare-gyare shine wanda aka fi amfani da shi kuma ana amfani da shi sosai.Madaidaicin net forming shine madaidaicin samfuran carbide siminti.samar da ci gaban bukatun.Hanyoyin gyare-gyare daban-daban suna da nau'i daban-daban na kayan gyare-gyare da gyare-gyare.Kayayyakin da ke da sifofi masu rikitarwa waɗanda ba za a iya yin su kai tsaye ta hanyar latsawa ba, ko samfuran waɗanda girman sa ya yi ƙanƙanta kuma ba su da tattalin arziƙi don yin wani nau'in gyare-gyaren latsawa, ana ƙara su ta hanyar injinan latsawa.

Lokacin aikawa: Janairu-05-2024