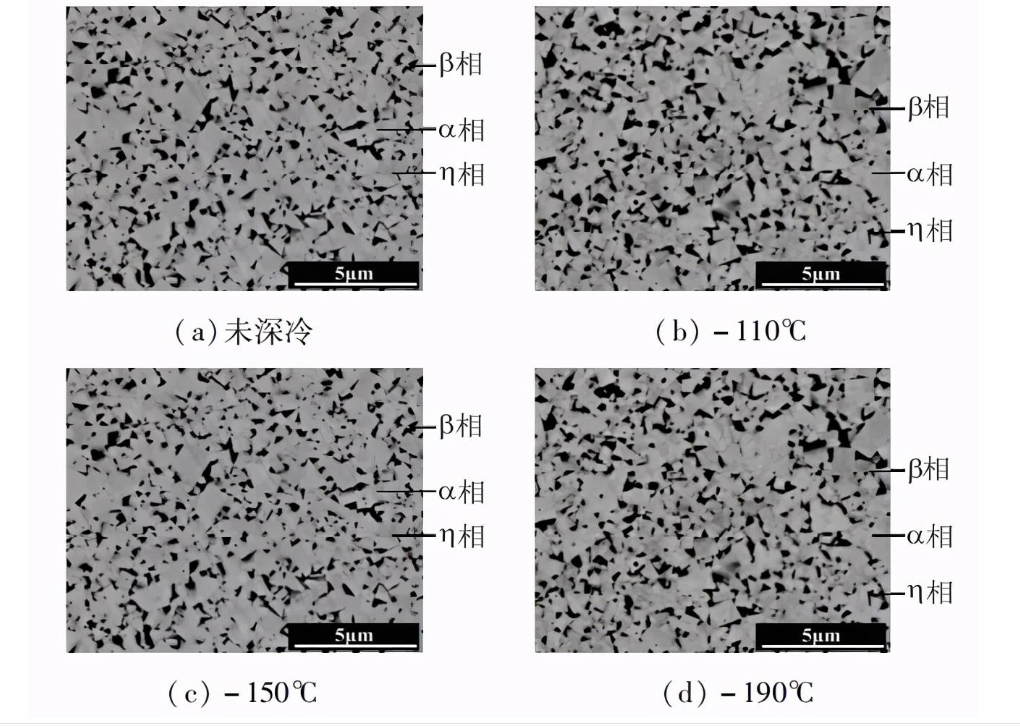

Lokacin da ƙarfe yayi crystallizes, polycrystal ne wanda ya ƙunshi hatsi da yawa.Ana iya bayyana girman hatsi ta adadin adadin hatsi a cikin juzu'in naúrar.Mafi girman lambar, ƙarami girman hatsi.Yawan hatsi a kowace naúrar giciye ko matsakaicin diamita na hatsi galibi ana amfani dashi don dalilai na aunawa.Girman hatsi na karfe yana da tasiri mai mahimmanci akan yawancin kaddarorin karfe.Tasirin girman hatsin tungsten carbide shine ainihin tasirin girman yankin iyakar hatsi.Mafi girman girman hatsitungsten carbide, Ya fi girma yankin iyakar hatsi kuma mafi girman tasiri akan kaddarorin.Domin dakin zafin jiki na inji Properties na karafa, kullum mafi kyau hatsi, mafi girma da ƙarfi da taurin, yayin da filastik da taurin ma ya fi kyau.Wannan shi ne saboda, mafi kyawun hatsi, ƙarin nakasar filastik kuma za a iya tarwatsawa a cikin mafi yawan hatsi, ta yadda mafi yawan filastik iri ɗaya.

nakasarwa, ƙarami ƙaddamar da damuwa na ciki;kuma mafi kyawun hatsi, mafi kyawun ƙirar ƙira, mafi girman iyakokin hatsi;Yawancin damar da za a yi amfani da hatsi da hatsi, mafi muni ga yaduwa da ci gaban fashe, da maƙarƙashiya juna, mafi kyawun ƙarfi da ƙarfi.Tebur ya lissafa tasirin girman hatsi akan kayan aikin injiniya na ƙarfe mai tsabta.Daga tebur za a iya gani don tata da hatsi don inganta inji Properties na karfe a dakin da zazzabi taka babban rawa, sabili da haka, yawanci ko da yaushe fatan cewaTungsten carbide kayayyakinabu mafi kyawun hatsi mafi kyau.

Amma a cikin aikin zafi mai zafi na kayan ƙarfe, hatsi yana da girma ko ƙananan ba su da kyau.Sabili da haka, yawanci suna son samun matsakaicin ƙwayar hatsi, amma a wasu lokuta fatan cewa hatsi ya fi girma kuma ya fi girma.Misali, kera injinan lantarki da na'urorin wuta irin wannan takardar karfen siliki ne, girman hatsi, karancin asarar tef, mafi girman inganci.A takaice dai, tasirin girman hatsi akan aikin karfe yana da yawa, zuwa takamaiman bincike na takamaiman halin da ake ciki

Lokacin aikawa: Juni-09-2023